Hydrogen Generators

Products:

High Purity Hydrogen Generators »

Hydrogen Generators »

FID Gas Station »

Rack Mounted Hydrogen Generator »

H2 Sensor for GC-MS / GC »

Products:

High Purity Hydrogen Generators »

Hydrogen Generators »

FID Gas Station »

Rack Mounted Hydrogen Generator »

H2 Sensor for GC-MS / GC »

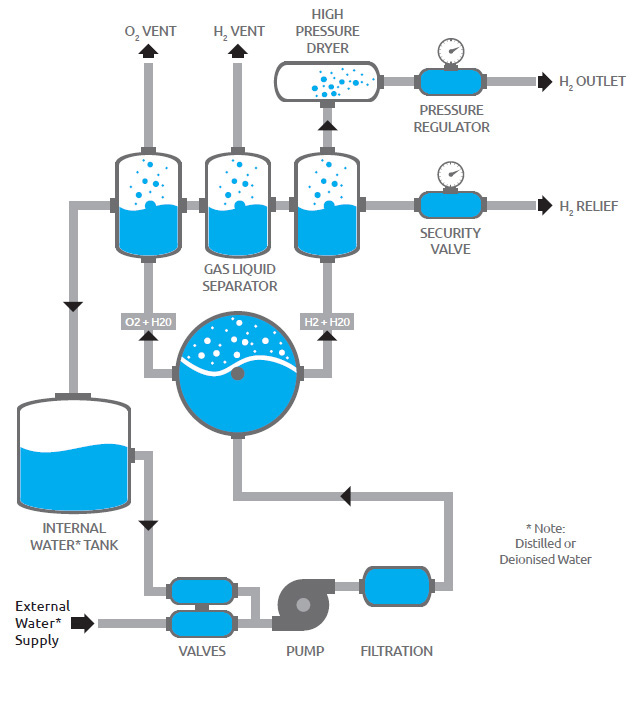

How Onsite Hydrogen Generation Works

IATT AiroGen® High Purity Hydrogen generators use Proton Exchange Membrane (PEM) technology to separate distilled or deionised water into its two main constituent gases of hydrogen and oxygen using hydrolysis.How PEM Hydrogen Generation Works... From an external water supply distilled or deionised water is pumped through a filter to remove any solid contamination. The clean purified water then passes into the Proton Exchange Membrane (PEM) where electrolytic dissociation separates the water into its two main components: hydrogen ready for analytical use, and oxygen that is released into the atmosphere.

The hydrogen for laboratory analytical use is then passed through either an integral single or double column desiccant dyer. No desiccant cartridge maintenance is require when using the double column dryer with automatic regeneration. This automatic drying system ensures the highest purity grade of hydrogen purity for analytical applications. No acid nor alkaline solutions are used in the hydrogen generation cycle.

What is Hydrolysis? – Hydrolysis, also known as Electrolysis, is the separation of water into oxygen and hydrogen gas due to an electric current being passed through the water. In an application such as Laboratory Hydrogen Gas Generation this takes place within a specially developed polymer electrolyte membrane.

{ Improved chromatography results with Onsite High Purity Hydrogen Generation